Construction works or installation of equipment always need to use silicone glue. The use of glue will come with some use of the glue gun. However, how to caulk without a gun, please read our article carefully.

We have researched and selected the necessary information for you to update when using glue products. You will also be updated with basic information on usage, advantages, and disadvantages of using the product. Plus, you’ll get an overview of the product. You also know the steps to use.

The article includes the following sections:

- The Reason Why Need Caulk Without A Gun

- Limitations when caulking without a gun

- Step By Step To Caulk Without A Gun

- Q&A

- Conclusion

Table of Contents

The Reason Why Need Caulk Without A Gun

Before talking about the limitations of how to caulk without a gun. I would like to provide you with more information about glue.

What is silicone glue?

Silicone glue is a compound consisting of silicon and oxygen atoms linked together, or the bond between silicone and organic groups in the form of polymer chains. In other words, they are made from silicon, additives or catalysts.

They have a physical state in the form of a liquid lake, which can solidify when exposed to moisture. Really good glues won’t dissolve, won’t corrode, won’t stain, be heat resistant and have good adhesion.

Reasons for not wanting to use a glue gun

Less amount of glue used

You may need to use silicone glue, but the amount you use is not too much and currently you only have a bottle of silicone glue and you use it.

You don’t have time to buy glue gun accessories

You are in urgent need of glue, you do not have enough time to buy a glue gun.

Limitations when caulking without a gun

Before talking about the limitations of how to caulk without a gun. I would like to provide you with more information regarding silicone sealants in terms of characteristics, silicone creams, etc.

General characteristics of silicone glue

- Dry fast

- High elasticity,

- Do not drip or dry halfway.

- Solid durability

- Do not deform or damage the surface of the material to be pasted

Some popular types of silicone sealant today

Some popular, widely used silicone sealants today are as follows:

- RTV glue: This is a self-curing glue at room temperature. They will be frozen when encountering moisture in the air, so when you proceed to apply, you need to be precise and fast.

- Acrylic silicone glue: The main material of this glue is acrylic polymer resin. They have a wide range of applications, especially being able to perfectly seal gaps.

- Polyurethane glue: This is a type of glue with very good corrosion and moisture resistance characteristics. The outstanding role is to be used as a very durable coating.

- Glass matt: This is a form of glue paste, used to join pieces of glass together.

Silicone glue is a type of glue with many outstanding advantages and high applications in today’s life. That is why they are widely used in construction projects, interior and exterior.

Outstanding uses of silicone sealant

Silicone glue is a type of glue with high application, especially used to handle and overcome problems that often occur at construction, interior and exterior projects as follows:

Helps seal cracks in the wall or holes in the roof, eel cracks, openings in door belts.

Capable of bonding stones, ceramic items and filling even ceramic wall tiles or floor tiles with peeling cement.

Helps to connect joints of tiles and effectively seal holes in water tanks and aquariums.

Advantages and disadvantages of silicone sealant

The following are the advantages and disadvantages of silicone sealant for you to consider when using:

The advantages

- The most outstanding feature of this glue is its good resistance to harsh weather conditions of the environment.

- Under the effect of ultraviolet rays or high temperatures, the silicone sealant still does not corrode or show any signs of damage.

- The most outstanding feature of silicone sealant is its ability to withstand water.

- They are resilient and extremely resilient.

- Silicone sealant is very durable over time and has a long service life.

- That is why this is the glue that is used a lot today.

The disadvantages

- Silicone sealant cannot be used with oily surfaces.

- They cannot be coated.

- Poor friction resistance is a disadvantage of this glue.

Limitations when caulking without a gun

When you do not use a glue gun you will encounter many limitations such as:

- The amount of glue comes out unevenly.

- You take the time to preserve the glue.

- There will be work interruption especially when you are working in construction.

- It will take your strength to let the glue come out.

Step By Step To Caulk Without A Gun

After you update the basic information about glue, glue gun, etc. This is the most important part of the article that tells you step by step to caulk without a gun. Not only do you know each step, but you also receive information from those steps. Now, read on!

Instructions on how to use silicone glue.

To use silicone sealant to get the most out of it, you need to follow these steps:

Step 1: Prepare

Prepare all necessary tools such as glue gun, detergent, protective gloves, tools, etc.

Before using silicone sealant, it is necessary to check the compatibility and adhesion of the product to the material surface.

Take care not to leave stains or stains on the surface.

Step 2: Clean the surface

Do not forget to clean the construction surface, remove dust or other dirt to help the surface become smoother and cleaner, the higher the adhesion efficiency will be.

You can use a clean cloth soaked in bleach and wipe the surface, or use toluene or acetone for a cleaner wipe.

Step 3: Use adhesive tape to protect the area that does not need to be attached or sealed.

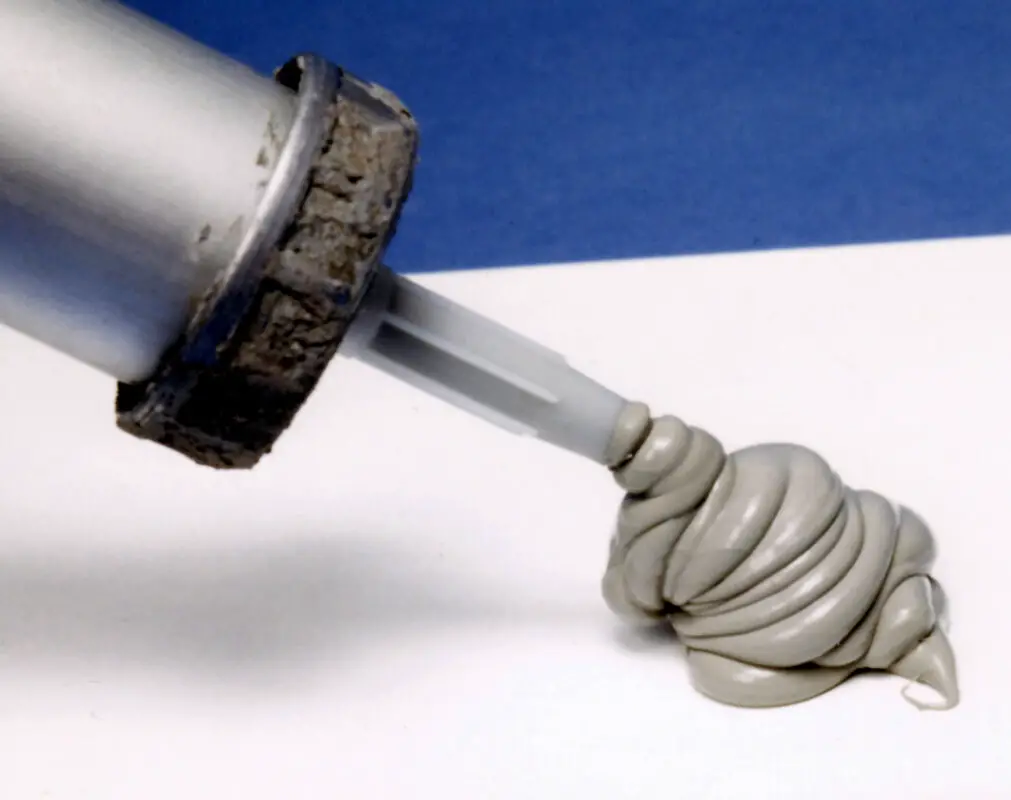

Step 4: Proceed to use silicone glue

Use a suitable wooden stick to insert the end of the silicone glue. Then you put the glue head on the part to be attached and use the force at the tail to push the glue out.

The thickness of the silicone sealant is determined by the critical temperature, distance, application and device temperature rise, and relative measuring structure. With a minimum thickness of 6.0 mm.

Step 5: Handle the excess

If there is excess, you need to remove the excess glue on the surface of the filling to make the glue more aesthetic.

Step 6: Wait until the silicone sealant hardens

Each different type of glue has a different curing time, so after the glue cures you need to peel off the protective tape around the glue area.

Q&A

1.How to distinguish different types of glue?

To distinguish silicone sealants, it is necessary to rely on the following factors:

Distinguish by color

- White silicone glue used in apparel or jewelry, handicrafts with high adhesion

- Gold silicone glue used to glue furniture, especially wooden furniture.

Sort by size, shape

- Glue toothpick: Glue has a small size, used for small positions, in the fields of household appliances and fine arts. The characteristics of toothpick glue are fast drying speed, good adhesion ability

- Granular glue: The shape is small pellets of various sizes with milky white or yellow color. The product is low cost, easy to transport.

- Plastic-based silicone sealant: Used in the cloth and diaper manufacturing industry. Time saving, high productivity.

2. How to use silicone glue with glue gun?

Step 1: Prepare the necessary things

Prepare all the necessary tools such as glue gun, bleach, protective gloves…

Before using the glue, it is necessary to check the compatibility, the adhesion of the product to the surface of the material, to avoid stains and stains on the surface.

Step 2: Clean

Silicone glue easily adheres to clean surfaces, helps increase durability after using the glue, so this is an essential thing that cannot be ignored before using the glue.

Clean the application surface from dust or other dirt to make the surface smoother and cleaner, the better the adhesion effect. You can use a clean cloth soaked in detergent and wipe the surface, or use toluene or acetone to clean

Step 3: Locate

Use adhesive tape to protect the area that does not need to be attached or sealed

Step 4: Use silicone glue

Use a glue gun with a silicone adhesive product attached to seal the space where it needs to be attached. Make sure there is enough space between the two mountings.

The thickness of the silicone sealant is determined by the critical temperature, distance, application temperature rise and relative measuring device and construction. The minimum thickness is 6.0 mm.

Step 5: Remove the excess glue on the filling surface so that the glue layer becomes more aesthetic.

Step 6: Wait until the Silicone glue cures

Different glues have different curing times. After the glue hardens. Peel off the protective tape around the sealing area.

3. Details of transparent silicone glue?

Transparent silicone glue

It is an adhesive with good adhesion on all types of surfaces such as walls, wood, metal, plastic, etc., especially glass and glass surfaces.

Therefore, this product is often used to perform operations such as:

- Filling holes that cause seepage in corrugated iron, cracks on the wall, cracks in glass, glass, etc.

- Decorate, stick/stick objects on glass doors, refrigerator doors, clothes, etc.

- Mounting signs, advertising panels, attaching bathroom glass, window frames, car glass doors, glass fish tanks.

Reliability

- Good adhesion on all surfaces and absolute resistance to peeling, including areas exposed to frequent water.

- Resistant to water pressure, high temperature, chemicals and external factors such as weather, humidity.

- Can resist dirt and limit mildew, keep silicone always clean, do not fade.

- Seal all gaps, even the smallest.

- Fast drying and good curing, no shrinkage, extremely high elasticity.

4. What is the condition of silicone glue?

For users of silicone sealant

- To use silicone sealant, the user must master the technique of using a glue gun and other tools.

- Users also need to know the basic connections:

- For elastic glue: Depth = width of joint

- For plastic glue: Depth = width of slot

- The information of surface materials to be able to handle errors that may be encountered during the construction process quickly and safely.

- Know the drying time of the glue to be more proactive in construction

- Under normal conditions (20°C and 60% humidity), the glue will dry 2-3mm within 24 hours. At first the glue went faster and then dried slowly.

With the surrounding environment of the construction site

Around the construction area, the following conditions must be met:

- Clean, no dust

- Explosion-proof ventilation

- Ambient temperature ranges from 10 to 40 degrees Celsius

- Humidity 40-60%

- The most popular types of silicone glue today

Some outstanding silicone adhesives are available on the market today

- RTV: This is a self-curing adhesive at room temperature. With the feature that it will harden when it meets moisture in the air, so when the construction is carried out, it must be accurate and fast

- Acrylic glue: This is a wood material whose main raw material is acrylic polymer resin. Glue has a wide range of applications, capable of perfectly sealing gaps.

- Polyurethane: This glue is very resistant to corrosion and moisture. Mainly used as a coating with high durability.

- Glass Matte: A form of glue paste. The main use is Used to join the pieces of glass together.

5. Is silicone tree glue dangerous to health?

Silicone tree glue is known as a high-quality adhesive product with outstanding effects and effective waterproofing, heat-insulating, sound-insulating properties used in many residential buildings, or other products. solid as aluminum and glass doors, glass facades, metal surfaces…

Moreover, silicone tree glue dries very quickly, has high elasticity, is not easy to corrode, and has no main color, so it can both adhere well and ensure the best aesthetic effect.

With such great uses, tree silicone glue is popular with many people, but consumers always have small concerns about whether the glue is safe or not or does it affect health? Because not only used on external objects such as glass doors, tree-shaped silicone building materials are also used with daily living items such as water purifiers, household appliances in direct contact with the human body. people.

But you can be completely assured because the silicone glue will not affect your health. However, the prerequisite is that you must choose for yourself quality branded products because if you use poor quality products, we cannot confirm the safety. its.

With a quality glue product with high durability as well as great corrosion resistance, you can rest assured when using it because it will not do any harm to your health at all.

However, you should also pay attention to the purpose of using acacia tree because there are many different types on the market with separate uses. Choosing the right product for your purpose will make your work more efficient and safer. Should pay attention to the parameters stated on the product packaging to understand the origin and use of the product. Checking product information not only helps you in terms of product quality and safety, but also helps you get into good habits no matter what other product you buy.

6. Is silicone sealant leak proof, fireproof and conductive?

Silicone sealant is good at preventing leaks even when used as a sealer on the roof thanks to its elasticity that does not crack. At the same time, the glue product has high temperature resistance, so it is used in the kitchen as an extremely effective fireproof silicone sealant.

So is silicone glue conductive? Are you afraid of electric shock when sticking the power outlet? With this, you can be assured of the insulating ability of silicone sealant. The product is not only insulated, but also protected against electrical leakage at safe indoor electrical connections.

Some common applications when using insulating silicone glue

- Protective sealing of electrical connections

- Seal open the power socket

- Plug the power cord into the corner of the wall

- Dead stickers for power plugs that are prone to slipping

- Seal open for burnt plugs

- Insulating silicone adhesive has good fire resistance, anti-leakage with high safety and efficiency.

7. What is the practical construction application of silicone sealant?

Silicon are synthetic polymers, made up of siloxane units, consisting of a functional group of two silicon atoms and an oxygen atom frequently combined with carbon and/or hydrogen. Silicon is generally heat resistant and elastic like rubber, used in sealants, adhesives, etc.

Silicone glue is a viscous liquid that, when exposed to the atmosphere outside for a short period of time, will form a rubber pad on the surface of the glue in contact with it, which can be used for adhesion of materials Various materials such as iron, aluminum, glass, wood, granite, ceramic tiles, concrete, ceramics, etc. In daily life, silicone sealant is used to glue many things such as furniture, electrical appliances.

Currently, silicone sealants are widely applied in many different fields, in construction we divide two main types as follows: structural silicone and waterproofing silicone.

Structural Silicone: A construction silicone gel used as an adhesive, ensuring high cohesion and safety. Often used in the generation of tempered glass of high-rise buildings to replace concrete walls, jobs requiring high safety and accuracy, sealing cracks…

Waterproof Silicone: Is a construction silicone used for the main purpose as a waterproof glue with good adhesion and high waterproofing, durable over time as well as adverse weather factors. Often used to paste all kinds of windows, glass doors, corrugated iron roofs, ventilation holes.

Currently, there are famous silicon manufacturers in the world such as: Elkem, JFE Steel, Nitol Solar, SunEdison.

8. What is the difference in information about rubber, silicone?

Rubber and silicone

They are polymeric materials with viscoelastic activity, commonly referred to as elastomeric. Silicone is distinguishable from rubber by its structure.Besides, silicone has more properties than ordinary rubber. Natural rubber occurs, or they can be synthetic. Based on this, silicone can be distinguished from rubber.

- Silicone is one of the elastomers or one of the rubbers.

- The backbone of silicone contains silicon and oxygen, while the backbone of most other rubbers contains carbon-carbon bonds.

- Silicone is more resistant to heat, chemical attack, fungal attack, UV and Ozone than normal rubber.

- Silicone is better than all other rubbers because of thermal insulation due to heat resistance.

- Silicone rubber offers special properties, which organic rubber does not have. Organic rubber has poor corrosion resistance at high temperatures while these properties are excellent in silicone rubber at the same temperature conditions.

Rubber

In general, all elastomers are considered rubber, in that the size can be changed mainly by pressing, and can be returned to the original size after removing the tension.

But natural rubber is what we think of when we consider rubber. Natural rubber is obtained from the rubber of Hevea Brasiliensis. Most rubbers contain polymer chains of carbon. However, silicone rubber contains silicon in the polymer chains instead of carbon.

Silicone

Silicone is a synthetic rubber. It is synthesized. Silicone consists of a backbone of silicon atoms with alternating oxygen atoms. Unlike other elastomers, silicone’s inorganic backbone makes it more resistant to fungi and chemicals.

Rubbers are used for many applications such as cookware, electronics, automotive applications, etc., because of their elastic behavior. Since they are waterproof materials, they are used as sealants, gloves. Rubber or elastomers are excellent materials for insulating purposes.

Of all rubbers, silicone is much better for insulation due to its heat resistance. Silicone rubber offers special properties, which organic rubber does not possess.

Conclusion

This article has provided you with useful information about silicone glue and also what you need to know about how to caulk without a gun. You also have more information regarding the advantages and disadvantages of silicone adhesives.

In addition, we also have a Q&A section to answer questions that may also have answered your concerns and concerns.

So we hope you can successfully use the above steps. Below I will share more about how to use how to caulk without a gun through the video for your reference. Don’t forget to click on the product link on Amazon to be able to own the best product for your home!